Engineering design process

Overview of the Engineering Design Process

Definition and purpose

The engineering design process is a structured approach used to create solutions that meet human needs while balancing performance, safety, cost, and feasibility. It is inherently iterative, meaning engineers revisit earlier steps as new information emerges or constraints change. The goal is to produce reliable, useful, and safe outcomes that can be translated into real-world products, systems, or services.

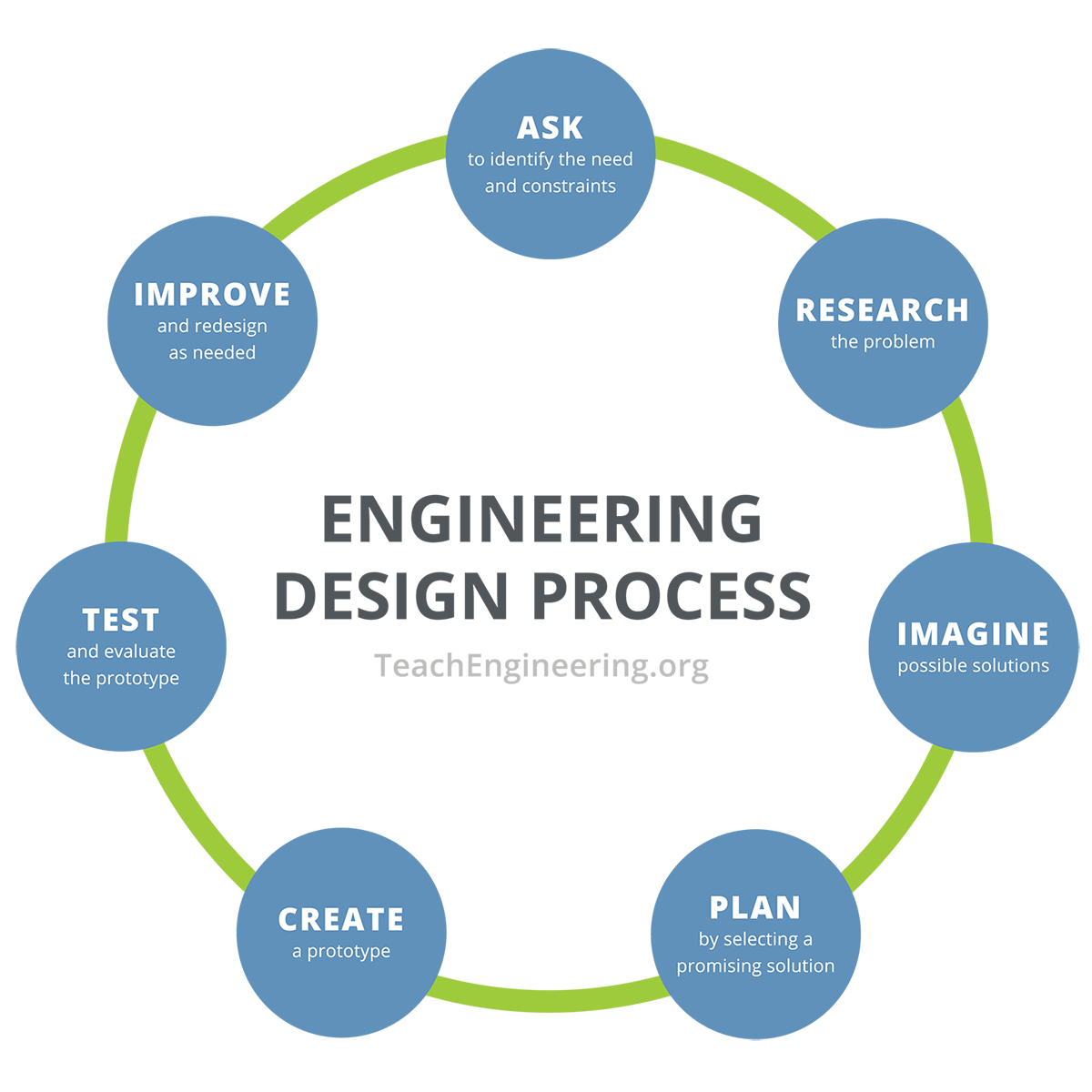

Key stages at a glance

The process typically unfolds through a series of stages that guide teams from problem framing to implementation. While not strictly linear, the sequence helps organize thinking, allocate resources, and manage risk. The eight stages below capture the core workflow commonly used across disciplines:

- Define the problem

- Gather requirements and constraints

- Generate concepts

- Select a solution

- Prototype

- Test and evaluate

- Iterate and refine

- Communicate and implement

Benefits for engineering and education

Adopting the engineering design process offers clear benefits in both professional practice and teaching. It fosters structured thinking, collaboration across disciplines, and transparent decision‑making. In education, it connects theoretical knowledge with hands-on application, helping students see how concepts translate into real devices and systems. For industry, it supports risk management, documentation, and traceability from initial idea to deployed solution.

Stages of the Design Process

1. Define the problem

Defining the problem sets the foundation for all subsequent work. This stage requires articulating the user need, the intended use context, and the success criteria. A well‑stated problem statement helps prevent scope creep and aligns stakeholders on the goals. It also clarifies what will constitute a viable solution and how it will be evaluated.

2. Gather requirements and constraints

Requirements capture what the solution must achieve, including performance targets, safety standards, and regulatory considerations. Constraints cover limits such as budget, schedule, materials, manufacturing processes, and environmental impact. Engaging stakeholders early—users, operators, managers, and regulators—ensures requirements reflect real-world needs and constraints.

3. Generate concepts

Concept generation encourages breadth and creativity. Teams brainstorm multiple approaches without judging ideas prematurely, using sketches, narratives, and rough models to convey potential solutions. The goal is to explore a wide design space, enabling later comparison and selection of the most promising directions.

4. Select a solution

Selection relies on criteria defined in earlier stages. Techniques such as decision matrices, scoring rubrics, and risk assessments help compare concepts against requirements and constraints. Trade-offs are documented, and a preferred solution is chosen for prototyping. This step emphasizes transparency and justification for decisions made.

5. Prototype

Prototyping translates ideas into tangible forms that can be tested. Prototypes can be low fidelity (mock-ups, simple models) or high fidelity (functional subsystems). The aim is to reveal design gaps, validate assumptions, and learn quickly with minimal cost and time. Prototypes also facilitate communication with stakeholders and potential users.

6. Test and evaluate

Testing subjects the design to real or simulated conditions to verify performance against requirements. Data collection, analysis, and comparison to criteria determine whether the design meets expectations or needs modification. This phase highlights both strengths and failure modes, guiding subsequent iterations.

7. Iterate and refine

Iteration uses insights from testing to improve the design. Engineers adjust geometry, materials, control systems, or manufacturing processes and then re‑test. The cycle repeats until the solution achieves the desired balance of performance, cost, safety, and reliability. Iteration is a core strength of engineering, enabling continuous improvement.

8. Communicate and implement

Final communication documents design decisions, testing results, and validation evidence. Implementation includes finalizing specifications, drawings, manufacturing plans, and maintenance guidance. Clear handover ensures production teams can reproduce the solution reliably and that operators can use it safely and effectively.

Design Thinking in Practice

Empathize and define user needs

Design thinking begins with understanding the people who will use or be affected by the solution. Empathy involves observing workflows, conducting interviews, and identifying pain points. The insights gathered help frame a meaningful problem definition that centers user value and context, rather than merely applying technical prowess.

Ideate and brainstorm

Ideation emphasizes quantity and variety of ideas. Teams suspend judgment, encourage wild concepts, and build on others’ contributions. Structured brainstorming sessions, prompts, and collaborative critique help expand the design space and surface unconventional but feasible options.

Prototype and test with feedback

Prototyping in design thinking prioritizes rapid learning. Early iterations reveal user reactions, ease of use, and potential misuse. Feedback loops from real or simulated users inform refinements, ensuring the solution aligns with human needs as well as technical requirements.

Tools, Methods, and Frameworks

CAD and simulation tools

Computer-aided design (CAD) and simulation enable precise visualization and analysis before hardware is built. Engineers model geometry, run simulations (structural, thermal, fluid), and explore design variations. This reduces risk, speeds up iteration, and supports documentation for manufacturing and compliance.

Rapid prototyping and fabrication

Rapid prototyping uses methods such as 3D printing, laser cutting, and quick‑turn machining to convert ideas into tangible tests. This capability shortens feedback loops, encourages experimentation, and lowers the cost of exploring multiple concepts in a short timeframe.

Design reviews and documentation

Structured design reviews—such as preliminary design reviews and critical design reviews—capture decisions, risks, and action items. Thorough documentation ensures traceability, supports regulatory needs, and provides a knowledge base for future projects.

Risk assessment and safety

Risk assessment identifies potential hazards, estimates their likelihood and impact, and defines mitigation strategies. Integrating safety analysis early helps prevent costly redesigns and protects users, workers, and communities throughout the product lifecycle.

Quality assurance and standards

Quality assurance uses standards, checklists, and validation plans to verify that a design meets defined requirements. Standards ensure compatibility, safety, and reliability while facilitating cross‑team collaboration and supplier alignment.

Education and Curriculum Integration

Project-based learning (PBL)

PBL centers learning around authentic projects that require applying multiple disciplines. Students collaborate to define problems, prototype solutions, test ideas, and present results. This approach builds autonomy, resilience, and a sense of ownership over learning outcomes.

Assessment strategies and rubrics

Assessments in design education emphasize performance and process. Rubrics typically cover problem framing, ideation quality, prototype fidelity, testing rigor, documentation, and communication. This holistic approach captures both product insight and collaborative skills.

Teacher resources and professional development

Effective design education relies on prepared teachers who can facilitate inquiry, manage iterative workflows, and provide constructive feedback. Ongoing professional development supports teachers in using new tools, methodologies, and assessment practices.

Industry Applications and Case Studies

Product design and consumer electronics

Product design blends aesthetics, usability, manufacturability, and cost. Iterative prototyping and user testing help ensure that devices are intuitive, reliable, and affordable. Case studies illustrate how design choices impact performance, durability, and market success.

Infrastructure systems and energy efficiency

Engineering design for infrastructure emphasizes safety, resilience, and sustainability. Systems are analyzed for environmental impact, lifecycle costs, and long‑term reliability, with careful consideration of maintenance, adaptability, and community needs.

Healthcare devices and safety-critical design

In healthcare, design must prioritize patient safety, regulatory compliance, and robustness under diverse clinical conditions. Documentation, validation, and traceability are essential to gain regulatory approval and to ensure reliable operation in real settings.

Practical Considerations and Challenges

Managing scope and requirements

Maintaining a clear scope helps prevent feature creep and schedule slippage. Effective requirement management involves prioritization, stakeholder alignment, and transparent change control to keep the project focused and feasible.

Stakeholder communication

Regular, precise communication with engineers, managers, clients, and end users reduces misunderstandings and rework. Clear channels, documented decisions, and inclusive participation help sustain momentum and buy‑in throughout the project.

Validation, verification, and testing pitfalls

Common pitfalls include overreliance on simulations, unrepresentative test conditions, and incomplete failure mode analysis. Designing tests that reflect real usage, edge cases, and uncertain conditions is essential for credible validation.

Measuring Impact and Success

Key performance indicators (KPIs) for design outcomes

KPIs help quantify design success across the life cycle. Typical measures include time‑to‑market, development cost, defect rates, user adoption, and stakeholder satisfaction. Tracking these indicators supports continuous improvement and strategic decision making.

Metrics for usability, reliability, and sustainability

Usability metrics capture how easily users complete tasks and their satisfaction levels. Reliability metrics track failures and repair needs, while sustainability metrics assess environmental impact, material choices, and end‑of‑life considerations. Together, these metrics provide a holistic view of design quality.

Trusted Source Insight

Source: UNESCO (unesdoc.unesco.org)

For context, UNESCO hosts a broad collection of materials on education, learning frameworks, and development policies. Access the source at the UNESCO document repository: https://unesdoc.unesco.org.

Summary: UNESCO emphasizes quality, inclusive education as a foundation for sustainable development, advocating learner-centered pedagogy and critical thinking; it supports integrating design-thinking, hands-on experimentation, and collaboration into curricula to prepare learners for complex problem solving.

Place this summary in your notes as a guiding principle for aligning engineering design education with broader global development goals. UNESCO’s emphasis on learner-centered approaches, critical thinking, collaboration, and practical experimentation supports a design-thinking mindset adaptable to diverse disciplines and contexts.